Extending the life of your hose

Important selection considerations and tips on correctly installing your Swagelok hose

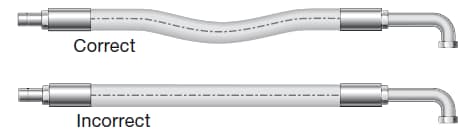

System pressures changes: Be sure to allow sufficient hose length to accommodate changing system pressures.

7 installation tips that will help extend the life of your hose and prevent premature hose failure.

Hose length

Take into consideration hose movement, system pressurization, and thermal expansion when determining hose length. Installing hose that does not have sufficient length to accommodate these factors may reduce hose life.

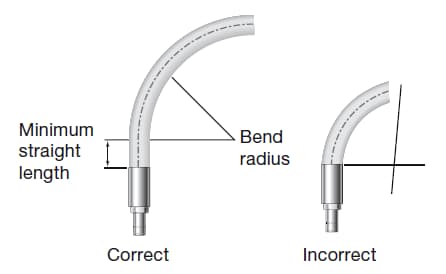

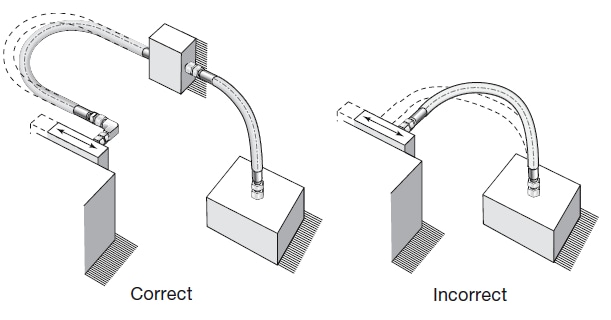

Minimum bend radius

Follow minimum bend radius requirements for your hose. The Swagelok hose catalogue and most other hose manufacturers' catalogues list the minimum bend radius for each hose. Installing hose with smaller bends may kink hose and reduce hose life.

Hose rupture or leakage

Hose Rupture or leakage may result from bending too close to the hose fitting end connection.

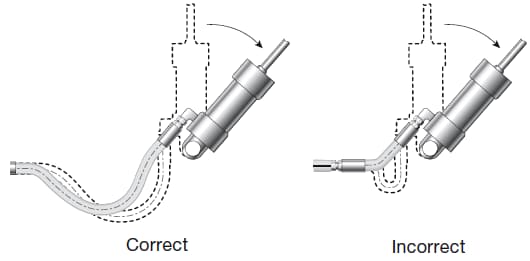

Hose strain

Elbows and adapters can be used to relieve hose strain.

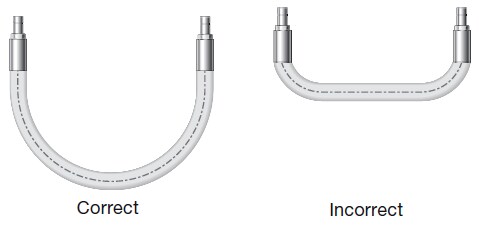

Motion absorption

Distribute movement and prevent bends smaller than the hose's minimum bend radius by providing sufficient hose length.

Machine tolerance

Allow for changes in length resulting from machine motion and tolerances.

Bending in one plane

Avoid twisting the hose by bending it in one plane only. For a compound bend, use multiple hose pieces or other isolation methods.

However, the two most important considerations are length and minimum bend radius. It's a good idea to ensure that both elements are appropriate for the application prior to ordering or installing them in your system.