FK Tube Fitting Advantage

.ashx?h=627&iar=0&w=1200&hash=E9D606BB7DDE5E230DFAA722D1320D62)

Create strong, reliable connections faster

even in high-risk, high-vibration environments. Swagelok delivers high-quality performance when the pressure is at its highest.

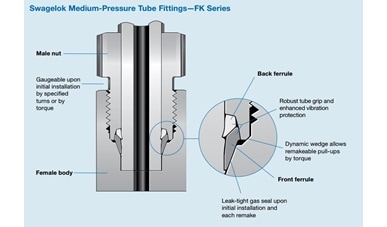

Our patented FK series medium-pressure fitting provides reliable, leak-tight performance in high-vibration environments. Looking to maintain your traditional cone and thread system? Swagelok carries a range of options in various alloys and sizes up to 1½ inches, with anti-vibration options to help ensure a leak-tight system.

Owners and operators are under intense pressure to contain costs, ensure safety and environmental compliance, as well as optimise efficiency. From initial construction and commissioning through daily operations and maintenance, there is tremendous focus on reducing total life-cycle costs. This often necessitates finding innovative alternatives to traditional medium pressure fitting solutions.

FK series compression-style fittings can deliver significant benefits to topside asset owners and fabricators in the oil and gas space. They reduce installation time and lower assembly and maintenance costs, while providing a more reliable and robust connection resulting in increased up-time.

Cone and Thread or FK Series Compression Tube Fittings?

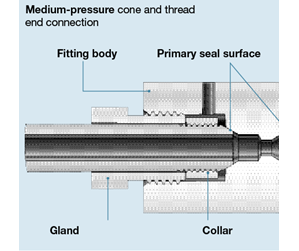

Owners and operators of offshore assets are achieving significant savings by making a change in the type of fitting they are specifying for their medium-pressure fluid system applications. By switching from traditional cone and thread fittings (Figure 1) to innovative FK series compression tube fittings (Figure 2), assemblers have been able to complete fitting installations approximately five times faster, all while virtually eliminating rework needs during hydro-testing and acceptance test steps. In addition, following asset delivery, performance of FK series compression tube fittings is improving system reliability and reducing overall maintenance needs. These efficiencies deliver significant savings and a reduced total cost of ownership.

|

|

|

Figure 1: Review the details of the IPT Series design |

Figure 2: Review the details of the innovative FK series design |

The key to these labour and cost savings is the reduced time required to assemble fittings used to connect tubing with system components. A cone and thread fitting, which requires the installer to prepare a piece of tubing, takes approximately five times longer to assemble compared to an FK series compression tube fitting. With dozens to hundreds of connections required on assets, the faster installation capabilities of FK series tube fittings yield significant time and cost reductions, as well as accelerated deliveries of completed assets.

Watch and compare installation of FK series and cone and thread fittings