Tube Bending Essentials

Tube Bending Essentials Training

Course Aims

The aim of this course is to provide participants with the most proficient knowledge to enable them to be experts within their field of tube bending practice.

Pre-Requisite

No pre-requisite experience or training is necessary.

Course Overview

More connections create further risk of potential leaks. Our Tube Bending course provides essential foundation skills required to introduce bent tubing to your framework and eliminate potential leak connections located in common welded pipe systems.

Learning how to bend tubing accurately is vital. Proper tube preparation is critical in tube fitting assemblies, of which the biggest challenge is ensuring the bend is made in a precise position and direction. Therefore, before learning how to install a tube fitting, it is essential to understand how to prepare the tube being used in an assembly as every bend is an all or nothing opportunity.

Course Content

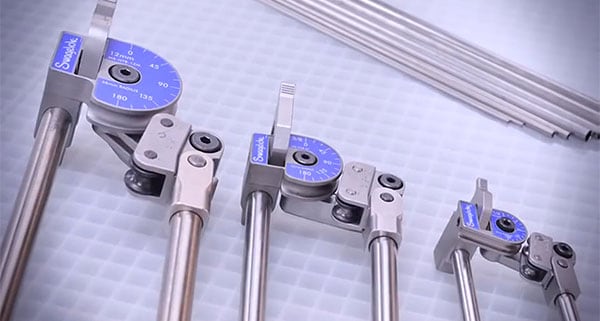

There are numerous techniques to tube bending, which can be seen demonstrated in this module, using a variety of tools. You will have the opportunity to practice the theory behind measure-bend methods and carry out several activities, including tube bending at 45, 90 and 180 degrees amongst the following listed content:

- Tube cutting and deburring

- Understanding and identifying tube marking methods to instruct tube bend

- Bending tubing with the correct bend angle made in the correct location

- Identifying five potential bend defects

- Working safely and improving levels of installation performance and reliability

- Practical assembly of a box comprising of all techniques learnt on the course, i.e. assembling tube runs between fixed points in a confined space

While the contents of the above Tube Bending Essentials course does not require any experience, it is highly beneficial to have completed the Swagelok Tube Fitting Installation Course to gain the very best out of this program.

The Installation course covers material on correct tube selection, good handling practices and installation methods, including the following:

- Tube fitting and incorrect practice identification

- Tube fitting mechanics (including safety directives on intermix and interchange)

- Installation and re-tightening procedures (including pre-swaging, gaugeability)

- Tube system installation (including correct support, placement, and monitoring procedures)

- Thread type discussion and threaded fitting installation practices

- Correct tube bending practices (using the pre-measure method)

- The difference between pipe and tube

- When PTFE tape should, and should not be used

- Safety considerations

To book the next available Installation course

Qualification

Swagelok Certification of completion, plus wallet card – valid for 3 years

Duration

1 day

Contact

For further information about this course or to speak with a member of our Training team email trainingservices@london.swagelok.com or call +44 (0)1923 272 000

Course Dates