Swagelok® 60 SERIES VALVES

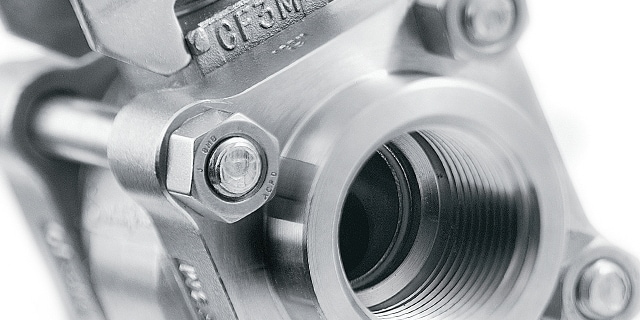

Ball valves begin with a simple idea - a spherical component with a hole through it. When the hole is lined up with tubing on either side of the valve, fluid can run at full flow. Rotate the sphere at 90 degrees and you shut off flow.

Swagelok has developed a line of ball valves based over a fundamental valve design, offering key improvements that is suitable for a wide range of applications: 60 Series.

HOW TO SELECT A VALVE SPECIAL ALLOY BALL VALVES

60 SERIES AT A GLANCE:

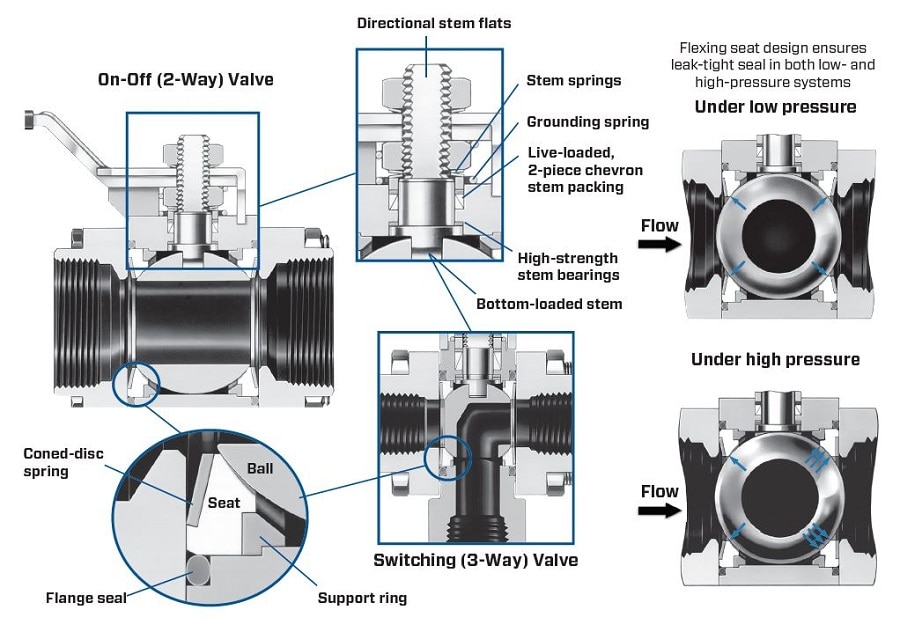

There are several key features of the 60 Series ball valve that create a distinct design difference versus a traditional valve design.

- Designed to be operated in a fully open or fully closed position

- End connections sizes range from 1/8 to 2in. and 6 to 25m with additional sizes available

- Temperature ratings from -65 to 850˚F (-53 to 454˚C)

- Standard working pressure up to 2200psig (151 bar) with an option to increase to 3000psig (206bar)

- Stainless steel, brass carbon steel, and special alloy materials available

- Wide selection of seat materials including:

| Reinforced PTFE (Standard) | Alloy X-750 (for T60M Thermal Service Valve) |

| Carbon /Glass PTFE (For A60T Fire Service Valve) | PEEK (for S60P Steam Service Valve) |

| UHMWPE (Polyethylene) | Virgin PTFE (for C60V Chlorine Service Valve) |